Cortinas opacas de dos colores para decoración del hogar, paneles con contraste creativo para sala de estar, cocina, costura opaca|Cortinas| - AliExpress

Gris Oscuro Color De Dos Tonos Ojal Superior Hotel Apagón Cortinas De Tela - Buy Cortinas De Hotel Negras,Tela De Cortina De Hotel Opaca,Cortinas De Hotel Opacas Product on Alibaba.com

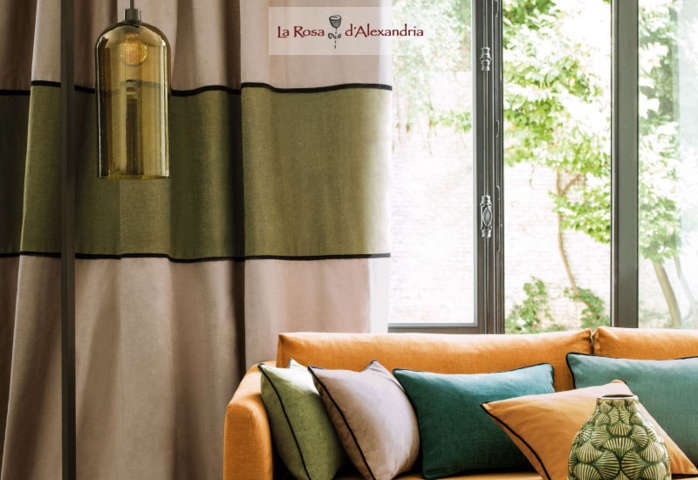

Cortinas de lujo de dos colores para ventana, artículos modernos para el hogar, cortinas opacas de alta calidad para sala de estar y dormitorio| Cortinas| - AliExpress

Cortinas opacas de costura de dos colores para el dormitorio, color Beige, azul, verde, rosa, gris, marrón, tamaño personalizado|Cortinas| - AliExpress

Cortinas dobles: cortinas de dos colores con degradado en forma de estrella, cortinas opacas con aislamiento térmico, cortinas con pliegues tipo lápiz, cortinas para dormitorio y sala de estar, cort : Amazon.es:

Amazon.com: BGment Cortinas translúcidas para habitación de niños, con ojales, de lino sintético, de dos colores degradados en vertical; cortinas decorativas para ventana de habitación de niñas, juego de 2 cortinas :

Cortinas confeccionadas, gruesa de color café asiática costura de algodón y arroz grises cortinas de tela